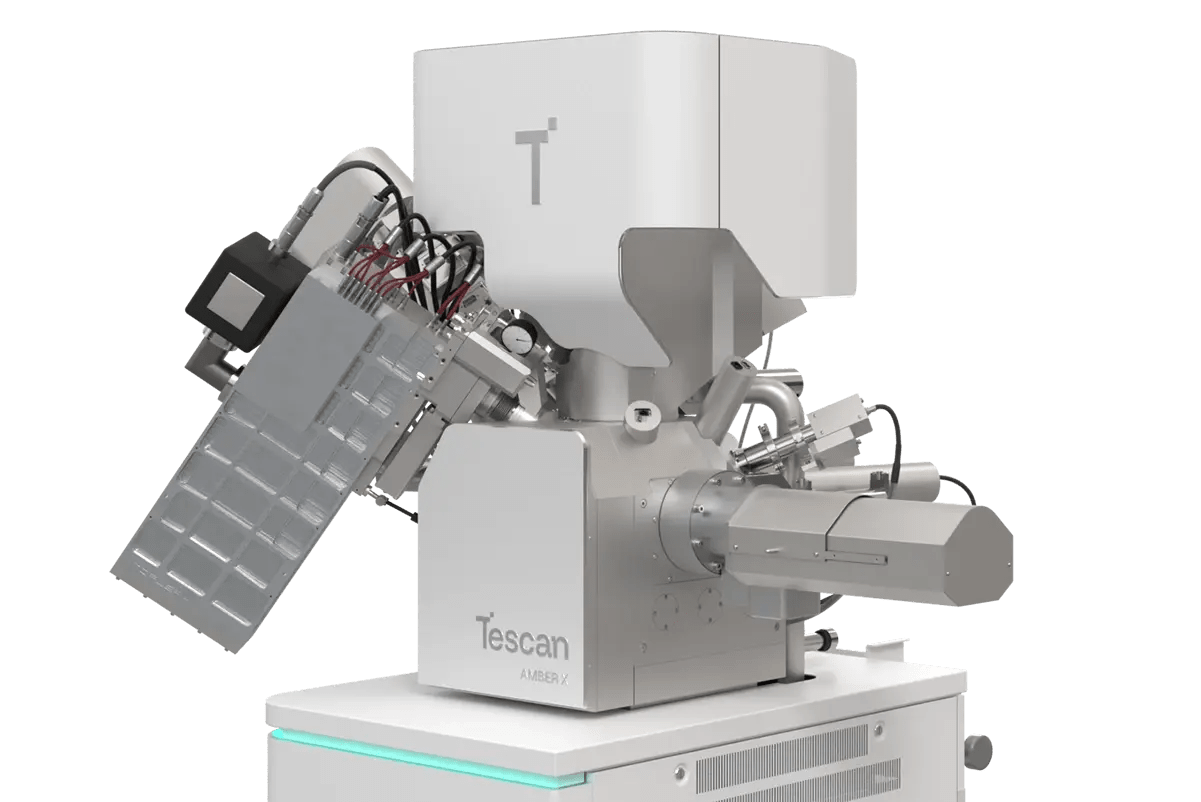

Introduction to TESCAN AMBER X2

TESCAN AMBER X2 is a high-performance plasma FIB-SEM engineered for high-throughput, large-volume material removal and precise nano-machining across semiconductors, materials science, and multi-scale 3D analysis. Equipped with a Xenon plasma ion source, it achieves extremely high milling rates with minimal damage, supported by TruBeam™ ion optics for beam stability and TruSlice™ 3D tomography for volumetric reconstruction. Integrated TESCAN Essence™ software provides unified dual-beam control, automation, and scripting workflows — delivering consistent, reproducible performance from trenching to 3D imaging. AMBER X2 bridges productivity and analytical precision, supporting both routine and advanced correlative applications.

Typical Applications

- Semiconductors & microelectronics: large-area cross-sections, TSV exposure, delamination and defect analysis.

- Materials science: 3D microstructural characterization, grain-boundary and inclusion studies, large-area trenching.

- Failure analysis: rapid interface inspection and defect localization with minimal sample preparation.

- Additive manufacturing: porosity mapping, layer-interface analysis, and 3D reconstruction of printed structures.

- Life sciences & geology: large-volume tomography of complex biological or geological materials under low-damage conditions.

Key Features

High-Throughput Plasma FIB Milling

- Xenon plasma ion source provides removal rates up to 50 × faster than Ga FIB with minimal thermal damage.

- Wide current range (1 nA – > 2 µA, continuously adjustable) enables both high-speed trenching and fine polishing.

- Excellent beam stability and uniform milling performance over extended operation.

TruBeam™ Ion Optics and Dual-Beam Geometry

- Optimized ion-to-electron alignment ensures precise coincidence at working tilt.

- TruBeam™ optics maintains consistent beam shape and minimizes redeposition.

TruSlice™ 3D Tomography

- Automated serial sectioning synchronized with SEM imaging for accurate 3D reconstruction.

- Real-time slice tracking and drift compensation guarantee geometric fidelity.

TESCAN Essence™ Automation Platform

- Unified SEM/FIB control with guided recipes, scripting and automation.

- Enables unattended multi-site trenching, 3D patterning and analytical workflows.

Advanced Analytics & Detectors

- Multiple detectors for SE, BSE, STEM-in-SEM and ion BSE signals.

- Fully compatible with EDS, EBSD, WDS, CL, cryo-CLEM and Raman integrations.

Versatile Chamber and Stage

- Spacious chamber with high port density for analytical accessories.

- 5-axis eucentric motorized stage ensures precise alignment and automation readiness.

Representative Technical Specifications

| Specification | Value (representative) |

|---|---|

| Ion source | Xenon plasma ion source |

| Ion beam current range | 1 nA – > 2 µA |

| SEM electron source | High-brightness Schottky FEG |

| SEM resolution | 1.2 nm @ 30 keV (SE); 3.5 nm @ 1 keV (In-Beam SE) |

| Ion beam resolution | < 20 nm @ 30 keV |

| Accelerating voltage (SEM) | 200 eV – 30 keV |

| Vacuum modes | High Vacuum; Variable Pressure (1 – 700 Pa) |

| Detectors (standard) | SE, BSE, STEM, ion BSE; optional CL, EDS, EBSD |

| Software platform | TESCAN Essence™ with TruSlice™ 3D, automation & scripting |

*Specifications may vary depending on configuration and installed options.

FAQ

What advantages does AMBER X2 offer over Ga FIB systems?

The Xenon plasma source achieves up to 50× higher milling rates than Ga FIB, ideal for large-volume cross-sections and 3D work with lower contamination and damage.

Can AMBER X2 perform 3D tomography automatically?

Yes. TruSlice™ 3D automates serial milling and SEM imaging to produce accurate 3D datasets with drift correction and geometric fidelity.

Does AMBER X2 support analytical techniques?

Yes. It integrates with EDS, EBSD, WDS, CL, and STEM-in-SEM for correlative analysis within the same workflow.

How is beam stability maintained during long milling sessions?

TruBeam™ ion optics actively stabilizes the beam shape and current to ensure uniform milling during prolonged runs.

Can AMBER X2 support cryo and correlative workflows?

Yes. It is fully compatible with TESCAN Cryo Solutions, CLEM and Raman systems for temperature-controlled and correlative experiments.

Overview of TESCAN AMBER X2

TESCAN AMBER X2 delivers a powerful combination of throughput and precision for advanced FIB-SEM applications. With its Xenon plasma source, TruBeam™ optics, TruSlice™ 3D tomography, and Essence™ automation, AMBER X2 accelerates time-to-data while maintaining exceptional accuracy for semiconductors, materials research and failure analysis.

Related Video / Webinar

- Webinar: -

- Video: -

Contact & Support

English (UK)

English (UK)  日本語 (Japan)

日本語 (Japan)  한국어 (Korean)

한국어 (Korean)  Tiếng Việt

Tiếng Việt  中文 (Chinese)

中文 (Chinese)