Introduction to TESCAN SOLARIS X 2

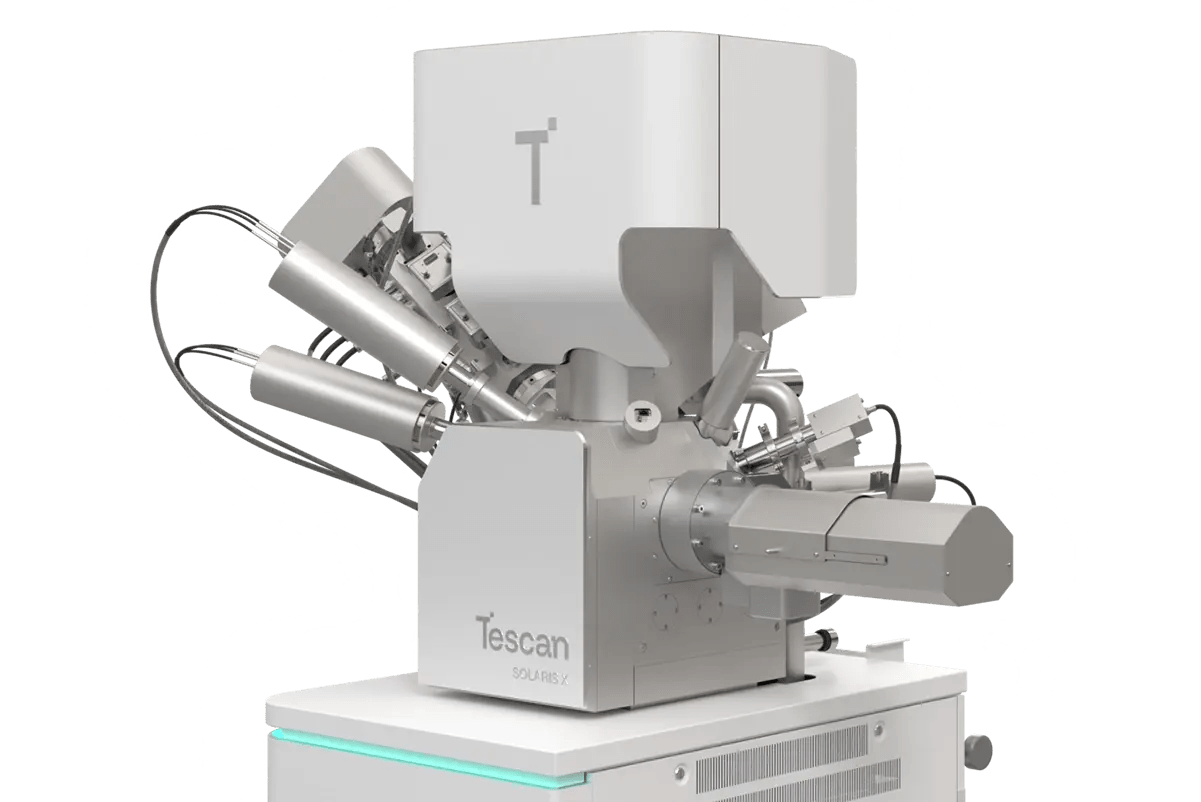

TESCAN SOLARIS X 2 is a Xe plasma FIB-SEM platform engineered for high-throughput nano-machining, Ga-free TEM sample preparation, and large-volume 3D analysis. With the Mistral™ plasma column and Triglav™ UHR SEM optics, it provides fast, uniform milling and stable, high-contrast imaging at low kV. Essence™ software unifies SEM/FIB control, automation, and TruSlice™ 3D tomography for consistent results across extended workflows.

Typical Applications

- Semiconductor FA & packaging: large cross-sections, TSV/die-stack exposure, delamination and void inspection.

- Ga-free TEM preparation: rapid trenching, lift-out, thinning and final polish without ion contamination.

- Advanced materials: large-area trenching, interface studies and microstructure mapping.

- Additive manufacturing & metallurgy: porosity and layer-wise evaluation, 3D reconstruction of printed parts.

- Life science & geoscience: high-contrast 3D imaging of porous/biological samples at low beam damage.

Key Features

High-Throughput Xe Plasma Ion Beam

- Xenon plasma ion source enables removal rates far beyond Ga FIB for fast bulk mill and large volumes.

- Stable beam at high currents supports uniform trenching and clean surfaces for tomography or TEM prep.

- Low contamination pathways suitable for Ga-free workflows.

Mistral™ Plasma Column & Dual-Beam Geometry

- Optimized column design for precise ion–electron coincidence at working tilt.

- Uniform sputtering performance across current setpoints with reduced redeposition.

Triglav™ UHR SEM Optics

- Schottky FEG with three-lens Triglav™ optics delivers sub-nanometer resolution and stable contrast at low kV.

- Wide field and depth of focus simplify navigation over large or complex samples.

Essence™ Automation & TruSlice™ 3D Tomography

- Unified SEM/FIB control with recipe editor, macros and scripting for unattended runs.

- TruSlice™ 3D synchronizes serial sectioning and imaging for accurate volume reconstruction.

Analytical & Correlative Integration

- Supports EDS, EBSD, WDS, CL, STEM-in-SEM and cryo-correlative options.

- Compatible with nanomanipulation and in-situ stages for dynamic experiments.

Flexible Vacuum & Sample Environment

- High-vacuum operation for clean analytics; variable pressure (1–700 Pa) for charging/porous materials.

- Spacious chamber with multi-port layout for detectors and automation accessories.

Representative Technical Specifications

| Specification | Value (representative) |

|---|---|

| Ion source | Xenon plasma ion source |

| Ion beam energy | 1 – 30 keV |

| Ion beam current range | 1 nA – > 2 µA |

| SEM electron source | High-brightness Schottky FEG |

| SEM accelerating voltage | 200 eV – 30 keV |

| SEM resolution | 1.2 nm @ 30 keV (SE); 3.5 nm @ 1 keV (In-Beam SE) |

| Ion beam resolution | < 20 nm @ 30 keV |

| Vacuum modes | High Vacuum; Variable Pressure (1 – 700 Pa) |

| Detectors (standard) | SE, BSE, STEM-in-SEM, ion BSE; optional EDS, EBSD, WDS, CL |

| Software platform | TESCAN Essence™ with TruSlice™ 3D, automation and scripting |

*Specifications may vary depending on configuration and installed options.

FAQ

What makes SOLARIS X 2 different from Ga FIB systems?

The Xenon plasma source delivers far higher milling rates and Ga-free sample preparation, ideal for advanced packaging and large-volume 3D applications.

Can SOLARIS X 2 perform fully automated 3D tomography?

Yes. TruSlice™ 3D coordinates serial sectioning and SEM imaging to produce accurate, drift-corrected volumes.

Is SOLARIS X 2 suitable for Ga-free TEM sample preparation?

Yes. Xe plasma milling supports fast trenching and high-quality final surfaces without Ga implantation.

How is beam stability maintained during long milling sessions?

The Mistral™ column and optimized ion optics stabilize beam shape and current for uniform milling over extended runs.

Does SOLARIS X 2 support analytical and correlative workflows?

Yes. It integrates EDS, EBSD, WDS, CL and STEM-in-SEM, and is compatible with cryo, CLEM and in-situ stages.

Overview of TESCAN SOLARIS X 2

TESCAN SOLARIS X 2 unites high-throughput Xe plasma milling with Triglav™ UHR SEM imaging and Essence™ automation. It accelerates time-to-data for failure analysis, semiconductor engineering and materials research while ensuring Ga-free preparation and reliable 3D results.

Related Video / Webinar

- Webinar: -

- Video: -

Contact & Support

English (UK)

English (UK)  日本語 (Japan)

日本語 (Japan)  한국어 (Korean)

한국어 (Korean)  Tiếng Việt

Tiếng Việt  中文 (Chinese)

中文 (Chinese)